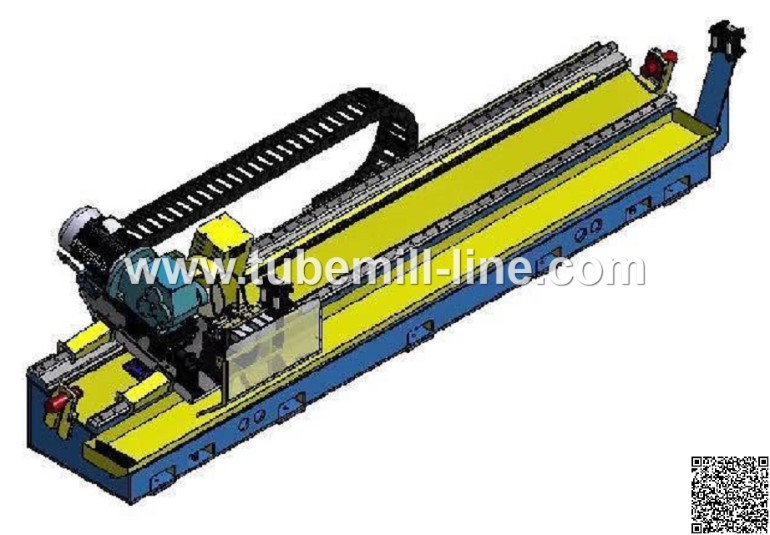

Tube Mill Cold Cutting Flying Cold Saw Cut Off for Tube Mill Line production

Checking the video for all types of running tube mill Flying Cold Saw Cut Off machine

Why choose the tube mill Flying Cold Saw Cut Off?

Provide the best pipe cutting performance to meet customer's requirement,

we made this tube mill cold cutting saw machine.

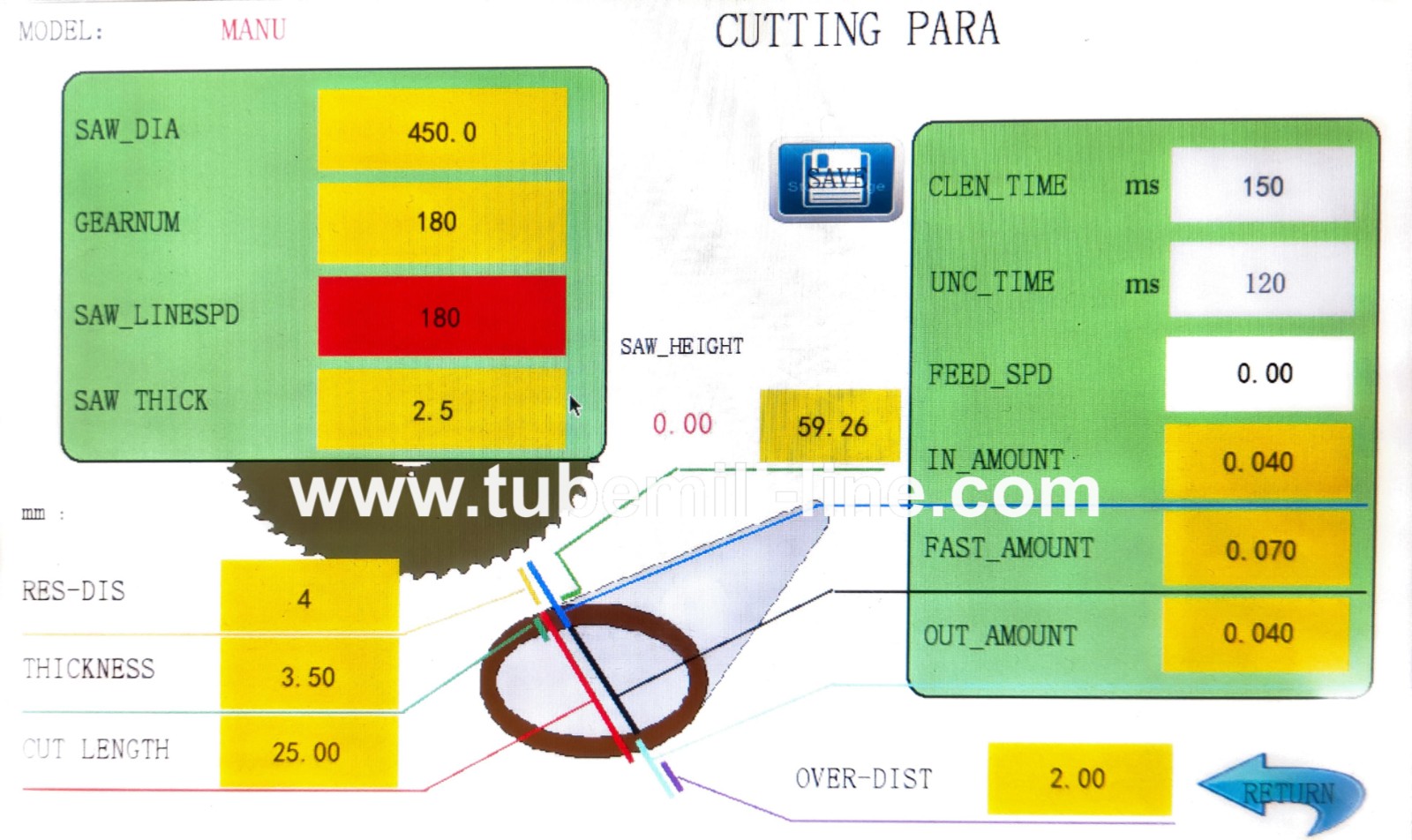

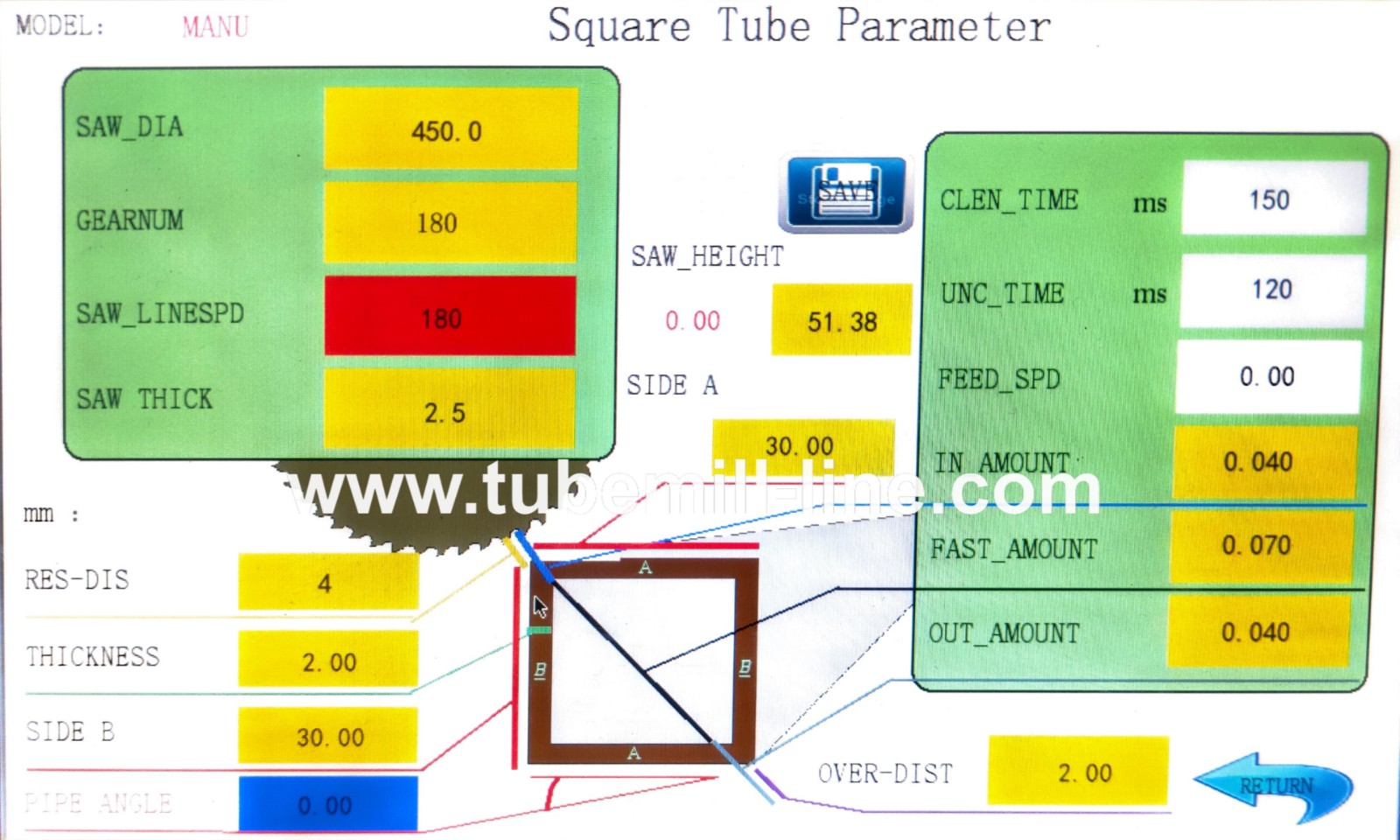

It is high technology, NC and intelligent.

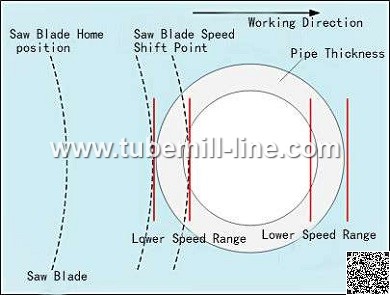

Set the optimized programme for the best cutting curve,

it will make the HSS/TCT circular saw blade a longer life, to safe the cutting cost.

It is very very convenient to input and do some modification of cutting parameters

Tube Mill friction / hot saw unit using friction circular saw blade, the heat produced from saw blade cutting, will be passed to pipes, cutting parts. It will cause high temperature saw blade and pipes, which will be harmful for human. Also, during the friction cutting, there will be fire flame during the hot cut process. Finally, the cutting surface is no smooth, but with burrs.

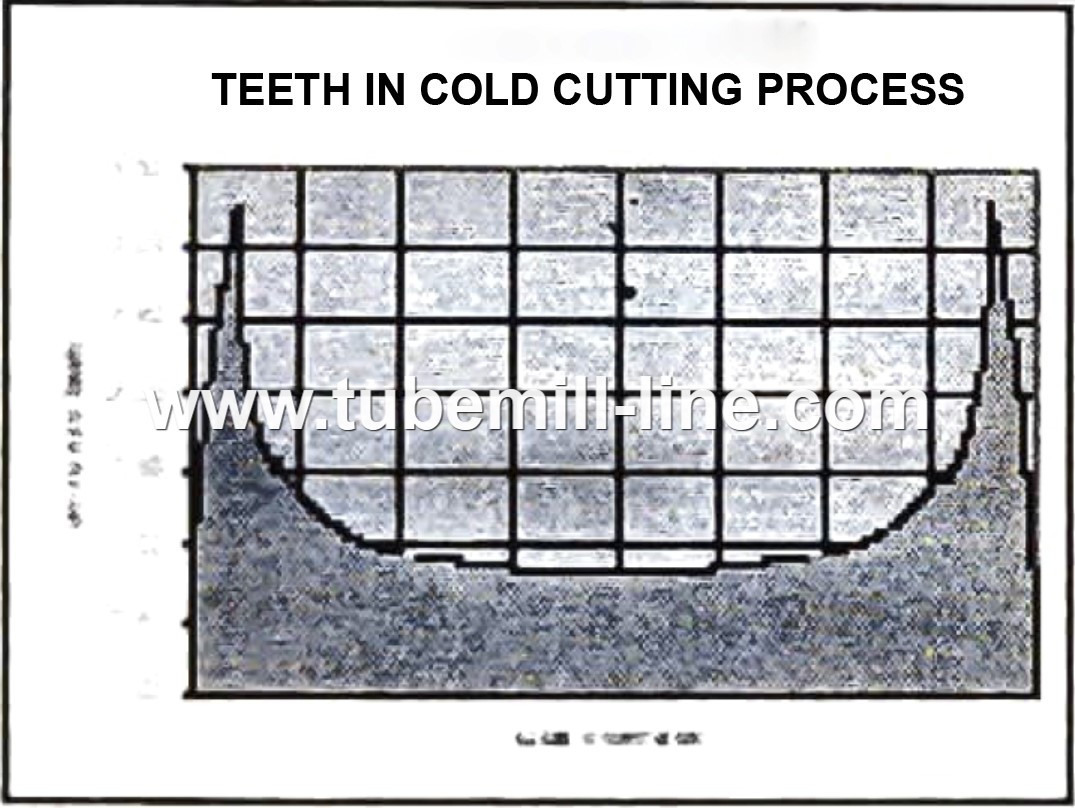

The Tube mill Flying Cold Saw Cut Off, seams like the milling saw unit, rotation speed is lower than hot friction saw. Pipe surface has no deformation or burrs, no need to use end-facing machine line to remove the burrs. Flying Cold Saw machine can save workload time and labor force, without spark, low noise, high safety, high production efficiency and high quality. Help our dear customer reduce the labor cost, reduce the edge-reprocessing machine cost, and improve the productivity and economical performance.

What is the difference between Hot saw and Flying Cold Saw?

The compare for the pipe cutting methods and cutting performance.

| Flying Cold Saw Cut Off | Computer / Friction / Hot Saw Unit | Tube Mill Flying / Cold Saw / Cut Off |

| Cutting Saw Photo |  |  |

| Cutting Accuracy | +5mm ~ -5mm | +1mm ~ -1mm |

| Burr | Much burrs there, the cutting surface is not smooth | Almost, no more burrs, the cutting surface is very smooth |

| Noise | Very Big Noise and flame fire | Only 25% noise as friction saw |

| Feeding for cutting | Pneumatic/Hydraulic power No any cutting Logic curve Friction hot cutting | By NC servo motor and screw Set the optimized cutting curve Milling cutting |

| Tube Raw material | Nomal Strength < 500Mpa | Nomal Strength < 1500Mpa |

| Saw Blade | Circular saw blade(Mn Steel) | HSS / TCT circular saw blade |

| Round Pipe |  |  |

| Solution | Chamfering/End facing machine line | No burrs, no need further process |

| Square/Rectangle |  |  |

| Solution | Manual polishing, big labor cost | No burrs, no need further process |

| Customized Profile |  |  |

| Solution | Manual polishing, big labor cost | No burrs, no need further process |

With many years development, we got so many good reputations from our customers.

High-quality key components are the basic elements for long life using.

The main axis driving motor is Seimens AC motor,

Feeding and cart driving motor is servo motor.

We adopt yaskawa drive and yaskawa servo motor as power system.

Only quality parts can bring you a perfect running performance.

Choose the right type from below table

Mainly, for tube mill Flying Cold Saw Cut Off, below models for your choose.

| Cold Cut Saw | Pipe Size Range(mm) | Max Speed (m/min) | |||

| Type | Round | Square | Rectangle | thickness | |

| MR25-B | Φ8~Φ25 | 20*20 | 15*25 | 0.5~1.5 | 120 |

| MR25-G | Φ8~Φ25 | 20*20 | 15*25 | 0.5~1.5 | 150 |

| MR25-Z | Φ8~Φ25 | 20*20 | 15*25 | 0.5~2.3 | 100 |

| MR32-B | Φ8~Φ38 | 30*30 | 20*40 | 0.5~1.5 | 120 |

| MR32-G | Φ8~Φ38 | 30*30 | 20*40 | 0.5~1.5 | 150 |

| MR32-Z | Φ8~Φ38 | 30*30 | 20*40 | 0.5~2.3 | 100 |

| MR50-B | Φ20~Φ63.5 | 50*50 | 35*65 | 0.8~3.0 | 110 |

| MR50-G | Φ20~Φ63.5 | 50*50 | 35*65 | 0.8~3.0 | 140 |

| MR50-Z | Φ20~Φ63.5 | 50*50 | 35*65 | 0.8~3.2 | 100 |

| MR60-Q | Φ25~Φ76 | 60*60 | 40*80 | 1.0~2.5 | 110 |

| MR60-B | Φ25~Φ76 | 60*60 | 40*80 | 1.0~3.2 | 100 |

| MR60-Z | Φ25~Φ76 | 60*60 | 40*80 | 1.0~4.0 | 90 |

| MR76-Q | Φ32~Φ89 | 70*70 | 45*90 | 1.2~3.2 | 80 |

| MR76-B | Φ32~Φ89 | 70*70 | 45*90 | 1.2~4.0 | 80 |

| MR76-Z | Φ32~Φ89 | 70*70 | 45*90 | 1.2~4.5 | 80 |

| MR89-Q | Φ38~Φ102 | 80*80 | 50*100 | 1.2~3.2 | 80 |

| MR89-B | Φ38~Φ102 | 80*80 | 50*100 | 1.2~4.0 | 80 |

| MR89-Z | Φ38~Φ102 | 80*80 | 50*100 | 1.2~4.5 | 80 |

| MR114-Q | Φ63~Φ114 | 90*90 | 60*120 | 1.2~4.0 | 70 |

| MR114-B | Φ63~Φ114 | 90*90 | 60*120 | 1.2~5.0 | 70 |

| MR114-Z | Φ63~Φ114 | 90*90 | 60*120 | 1.2~6.0 | 70 |

| MR127-Q | Φ60~Φ127 | 100*100 | 75*145 | 1.2~4.0 | 70 |

| MR127-B | Φ60~Φ127 | 100*100 | 75*145 | 1.2~6.0 | 70 |

| MR127-Z | Φ60~Φ127 | 100*100 | 75*145 | 1.2~6.5 | 60 |

| MR165-Q | Φ76~Φ168 | 130*130 | 90*180 | 1.5~4.0 | 60 |

| MR165-B | Φ76~Φ168 | 130*130 | 90*180 | 1.5~6.5 | 60 |

| MR165-Z | Φ76~Φ168 | 130*130 | 90*180 | 1.5~6.5 | 60 |

For more support, please contact: info@com-spare.com