How to choose a right steel tube mill line?

FAQ:

1, What is your required tube/pipe OD range? Wall Thickness range? Any other profiles?

We will do the necessary calculations and put out the idea about how to save the steel tube mill roll mould cost

2, What is your pipe used for? Can you share some applications?

With our rich experience and professional background, will share with you our successful projects in history.

3, Do you have any plan to visit our factory?

We will take you to visit the running steel tube mill machine line in China, to know more about us.

Why us?

1, More than 20 years R&D and manufacture experience. Tube Making industry, 100% performance guarantee.

2, China's leading ERW steel tube mill machine line manufacturer, In-depth knowledges of the latest tube&pipe making technologies.

3, Over 200 steel tube mill machines sold every year on the market. Good quality and reputation is the most important.

How we make the steel tube mill machine line in our factory?

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

What is the function about the steel tube mill machine line?

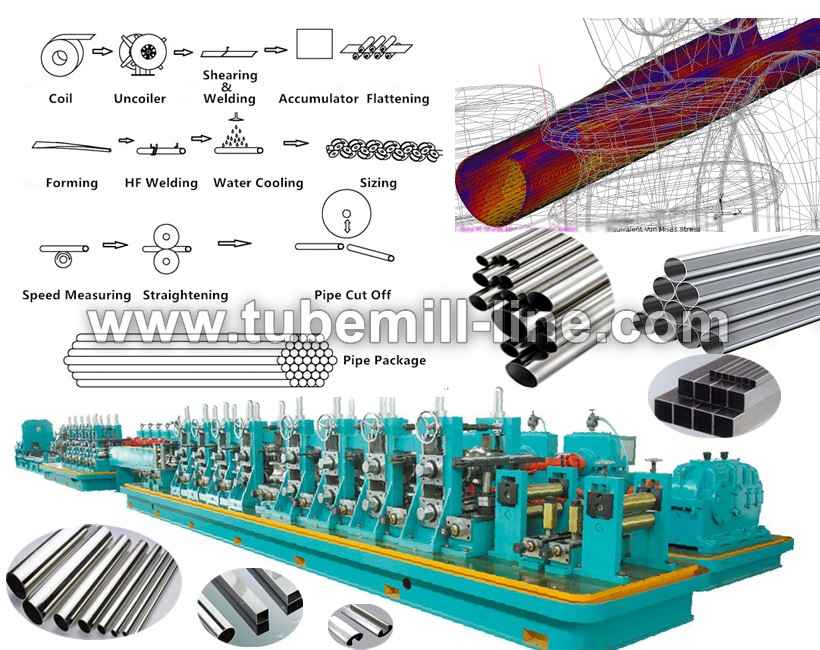

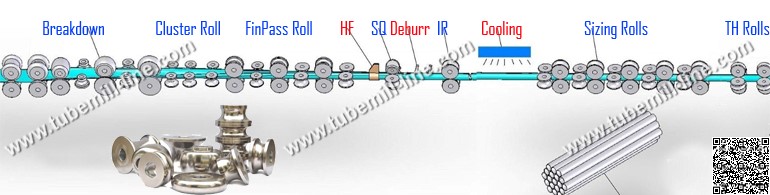

steel tube mill produce pipe and tube by taking a continuous strip of material from Uncoiler, accumulator/storage cage, and continuously roll forming, from breakdown roll stand/stations to fin-pass roll tooling stand/stations until the edges of the strip meet together at a welding station with SQ roller pushing/extrusion force. At this point the HF welding process melts and fuses the edges of the tube together and the material exits the weld station as the welded tube. Basic components include an uncoiler, straightener, Shearing butt & welding, forming section, fin pass section, welder, ID and/or OD scarfing, sizing section, cut off and stacker or runout table.

Each pass in the various sections are made up of a upper and lower shaft that installed with steel tube mill roll tooling mould which forms the steel strip gradually into a round shape or square if it is a form square / weld square type of mill. This gradual shape forming process is commonly according to the flower arrangement.

Roll design is a key element of the process and our engineers will work closely with customers to ensure that the end product meets specification and good quality.

Carbide rolls or inserts are also available where high volume production is required.

HG50 Steel Tube Mill Line for making welded steel tube(Φ19-Φ63.5mm)

Brief specifications

No | item | numerical value |

1 | Round pipe diameter | Φ19mm~Φ63.5mm |

2 | Round pipe thickness | δ0.6mm~2.7mm |

3 | Square tube size | 15×15~50×50mm |

4 | Square tube thickness | δ0.6mm~2.2mm |

5 | Rectangular tube size | 10×20~40×60mm |

6 | Rectangular tube thickness | δ0.6mm~2.2mm |

7 | Rolling speed | 30M/min~100M/min |

8 | Length of tube | 4M~8M |

Pictures for your reference

|  |  |  |

| steel tube mill Uncoiler | Butt Shearing & Welding | Storage Cage/Accumulator | steel tube mill Forming part |

|  |  |  |

| SQ Welding Section | steel tube mill Sizing Stations | steel tube mill Hot saw | steel tube mill Cold cutting |

|  |  |  |

| Run out table | Operation table | Water-Water Cooling Device | Rectifier cabinet |

|  |  |  |

| Inverter output cabinet | DC speed controller | Transformer | steel tube mill Roll Tooling |

Any more steel tube mill line models?

| Model | Tube OD (mm) | Wall Thickness (mm) | steel tube mill Speed | Main Motor Power | HF Power |

| HG 16 | Ø8 ~ Ø25 | δ0.25 ~ δ1.0 | 30~120 m/min | 37 KW | 100 KW |

| HG 25 | Ø8 ~ Ø32 | δ0.35 ~ δ1.3 | 30~120 m/min | 45 KW | 100 KW |

| HG 32 | Ø12.7 ~ Ø38.1 | δ0.5 ~ δ1.8 | 30~120 m/min | 90 KW | 150 KW |

| HG 45 | Ø12.7 ~ Ø50.8 | δ0.6 ~ δ2.3 | 30~120 m/min | 132 KW | 150 KW |

| HG 50 | Ø19 ~ Ø63.5 | δ0.6 ~ δ2.7 | 30~100 m/min | 160 KW | 200 KW |

| HG 50-76 | Ø19 ~ Ø76 | δ0.6 ~ δ2.7 | 30~100 m/min | 160 KW | 200 KW |

| HG 50-95 | Ø25 ~ Ø95 | δ0.7 ~ δ2.5 | 30~90 m/min | 185 KW | 200 KW |

| HG 60 | Ø19 ~ Ø76 | δ0.8 ~ δ3.5 | 30~90 m/min | 200 KW | 250 KW |

| HG 60-102 | Ø25 ~ Ø102 | δ0.8 ~ δ3.0 | 30~80 m/min | 200 KW | 250 KW |

| HG 76 | Ø25 ~ Ø95 | δ1.0 ~ δ4.0 | 30~70 m/min | 200 KW | 300 KW |

| HG 76-127 | Ø38 ~ Ø127 | δ1.2 ~ δ4.0 | 30~70 m/min | 110 KW x 2 | 300 KW |

| HG 89 | Ø38 ~ Ø102 | δ1.2 ~ δ4.5 | 20~60 m/min | 132 KW x 2 | 400 KW |

| HG 89-127 | Ø38 ~ Ø127 | δ1.2 ~ δ4.5 | 20~60 m/min | 132 KW x 2 | 400 KW |

| HG 89-140 | Ø50.8 ~ Ø140 | δ1.2 ~ δ4.5 | 20~60 m/min | 132 KW x 2 | 400 KW |

| HG 114 | Ø50.8 ~ Ø127 | δ1.5 ~ δ5.0 | 20~60 m/min | 160 KW x 2 | 400 KW |

| HG 114-165 | Ø76 ~ Ø165 | δ2.0 ~ δ5.0 | 20~60 m/min | 185 KW x 2 | 400 KW |

| HG 165 | Ø76 ~ Ø165 | δ2.0 ~ δ6.0 | 15~50 m/min | 185 KW x 2 | 500 KW |

| HG 219 | Ø89 ~ Ø219 | δ2.5 ~ δ8.0 | 15~50 m/min | 200 KW x 2 | 500 KW |

Customized specifications are avaliable, inquiry us for your tube mill line, today !